Products

Spectacle-Blinds-Spade-Ring-Spacer-Interlock

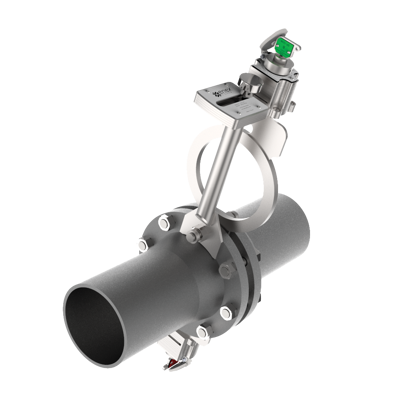

Product Model: H-SPiL

Spectacle Blinds are generally applied to permanently separating pipe flanges. A Spectacle Blind is a steel plate cut into two discs of a certain thickness. The two discs are attached to each other by section of steel similar to the nose piece of a pair of glasses. One of the discs is a solid plate, and the other is a ring, whose inside diameter is equal to that of the pipe flange.

Spectacle Blinds are applied in systems, which regularly need to be separated from other installations. Normally, a Spectacle Blind is mounted in the "open" position so that flow through the pipe is possible. If the Spectacle Blind in the "open" position is rotated, the pipe is blanked off and no flow is possible.

Maintenance on a pipe line or changes to process flow routes can be a reason to rotate the spectacle blind in the "close" position. This change over will take place by rotating the Spectacle Blind through the hole in the interconnecting section. By loosening of all bolts, and removal of all but the pivoting bolt, the Spectacle Blind can be rotated. After replacing the gaskets, the bolts can be re-assembled and tightened.

Spades and Ring Spacers are basically the same as Spectacle Blinds, except that both are not attached to each other. Spades and Spacers can be applied in systems where maintenance is often not necessary, or in applications with large pipe sizes. Depending on the flange size and the Pressure Class, Spades can weigh hundreds of pounds. To prevent unnecessary weight on the flange connections, usually Spades & Ring Spacers will be chosen in place of Spectacle Blinds.

SEQUENCE OF OPERATION

ENEX i-LOCK Series H-SPiL is the heavy industry Spectacle Blind, Spade and Ring Spacer Mechanical Trapped Key Safety Interlock product range. It is suitable for the full range of pipeline sizes and pressure classes. The H-SPiL ‘Patented’ lock portions and keys allow for either dual or single trapped key sequential or standalone operational procedures. The basic principle of this safety equipment is to lock the spectacle blind, spade or ring spacer at a predetermined position. For dual key system requirements, only if both rotary keys are inserted and rotated 90°;, will the internal locking mechanism housed within the ENEX i-LOCK be released allowing the host equipment to be operated. For single key systems, inserting and rotating the individual key, will release the ENEX i-LOCK internal locking mechanism allowing the host equipment to be operated. Each lock portion and rotary key is uniquely coded to allow a truly safe operating sequence procedure. Once the host equipment operation has commenced, the initially inserted key will be trapped and only when the host equipment has reached the opposing predetermined position will the next sequential key be released.

H-SPiL product range can be supplied with on/off switches and proximity limit sensors to confirm :

- Key entry rotation or key removal rotation

- Valve locked open &/or closed positioning

- Chemical

- Marine

- Mining

- Mineral & Cement

- Oil & Gas

- Petrochemical

- Power Generation

- Pulp & Paper

- Refining

- Water & Utilities

ENEX i-LOCK H-SPiL series of products supplied on Valves, Spectacle Blinds, Spades & Rings are normally provided on critical systems where incorrect operator action or operating the valve, spectacle blind, spade or ring inadvertently (in error) could lead to unsafe conditions arising.

The normal operations position of all the above shall be recorded and logged on a register (database) which is maintained at each location.

During abnormal operation, maintenance or extended period of isolation the ‘status’ (position) of valves, spectacle blinds, spades and rings can be changed for process integrity and personnel safety reasons. Changes made to the position of valves, spectacle blinds, spades and rings shall be through the site PTW (permit to work) system and controlled by the the ENEX i-LOCK – Mechanical Safety Trapped Key Interlock ‘Key Transfer’ products installed on the valves, spectacle blinds, spades and rings.

- ISO 14119:2013 (formally EN1088)

- Salt Mist Test (Lloyds Test Spec No 1)

- Fire Test (API 607 & ISO 10497:2010)

- High Temp Test 70c (EN 60068-2-2:2007)

- High Humidity Test (EN 60068-2-2:2007)

- Static and Dynamic Inclination (IEC 60092-504:2001)

- Ultra Low Temp -57c (EN 60068-2-1:2007)

- Vibration Test (EN 60068-2-6:2008)

- Ingress Protection Test (EN 60529:1992 Amd 1&2)

- Directive 2006/42/EC

- UK Designed, Engineered, Manufactured, Assembled & Tested Products

- Minimum 3 billion - billion! ‘unique’ Rotary Key Code permutations from the ‘Patented’ Lock Portion & Key Design. We stopped counting at 3 billion !

- Ultimate Safe and Secure Mechanical Interlock Design.

- Defeat, override & tamperproof compliant

- Solid and robust construction with no cast parts

- Materials of construction : Stainless Steel

- Unique ‘Patented’ Lock Portion & Key Design.

- Lock Portion and Key Design have been tested to over 100’000 cycles

- Lock Portion and Keys include ‘over torque’ protection mechanism as standard

- Tamper proof and copy proof body housing, lock portions and keys

- Unique ENEX i-LOCK tamper proof securing bolts

- Unique on the ‘Patented’ key is that the code and drive members function independently

- One single Master Key covers site installed Key Code permutations

- Ultimate product design for normal, harsh and corrosive environments

- Spring loaded Lock Portion Ingress Protection & Weather Seals Dust Caps

- No interference or intrusion of the host equipment pressure envelope

- Product serial number traceability on every unit

- Secure mechanical fixing of all labels and tags

- Full colour coded key & dust cap tagging option for enhanced error elimination

- Pad lockable dust covers are an option for lockout hasp and scissor hasps operation

- Trapped Keys can have scissor hasps attached to cover multiple trade personnel working on/in a given area.

- For Spectacle Blinds, where switching position is carried out by pivoting around one flange stud, this is a special manufactured flange stud, nuts and security collects. The security collects eliminate the removal of the flange stud nuts without totally destruction of the stud ends.